Full analysis of circular connector technology

1、 Basic Structure and Classification

1. Contact type

(1) Classified by contact form

Pin and socket system

Male head (pin): cylindrical/rectangular cross-section, material hardness>100HV

Female head (socket): elastic spring design, contact pressure range 0.5-3N

Single contact and multi contact

Micro connector: 0.4-1mm diameter micro pin

High power contact: silver plated copper pillar with a diameter of up to 10mm

(2) According to material and process

Material type Surface treatment Electrical resistivity (μ Ω· cm) Applicable scenarios

Phosphorus bronze gold plating 2 μ m 7.2 high-frequency signal transmission

Beryllium copper alloy silver plated 5 μ m 3.8 high current carrying capacity

Stainless steel passivation treatment 72 corrosion environment

2. Driving mode

(1) Threaded coupling type

Rotation turns: 1.5-5 turns

Anti loosening design: spring washer/self-locking thread

(2) Bayonet style

Locking angle: 30 °~90 °

Quick plug and unplug time:<2 seconds

(3) Push pull type

Holding force: 20-200N

Emergency Relief Structure Design

3. Installation method

(1) Panel installation

Thickness adaptation range: 1-10mm

Sealing scheme: rubber gasket/sealant

(2) Cable installation

Tensile strength:>100N

Bending life:>5000 times (R=8D)

(3) PCB installation

Solder joint type: direct insertion/surface mount

Thermal expansion coefficient matching: CTE<18ppm/℃

2、 Core performance parameters

1. Electrical performance

(1) Current carrying capacity

Calculation formula: I=K · S ·√ (Δ T/t)

(K material coefficient, S cross-sectional area, Δ T temperature rise, t time)

Typical values:

Signal contact: 1-5A

Power contact: 10-200A

(2) High frequency characteristics

Impedance matching: 50 Ω/75 Ω optional

Standing wave ratio:< 1.3@6GHz

Interference:< -60dB@1m Line length

2. Mechanical properties

(1) Mechanical characteristics of insertion and extraction

Specification insertion force (N) extraction force (N) service life (times)

Micro 2-5 1-3 500

Standard 10-30 5-15 5000

Industry 50-100 30-80 10000

(2) Environmental tolerance

Temperature cycle: -65 ℃~+200 ℃ (military grade)

Vibration test: 10-2000Hz, 50g acceleration

Salt spray test: 1000h@5 %NaCl

3. Protection level

IP level dustproof ability and waterproof performance testing conditions

IP67 fully dustproof, 1m water depth, 30 minute negative pressure test

IP69K anti high pressure spray 80 ℃ hot water flushing DIN 40050

3、 Advanced technical indicators

1. Electromagnetic compatibility

Shielding effectiveness:> 90dB@1GHz

Transfer impedance:<5m Ω/m

Filter contact: Integrated π -/C-type filter

2. Adaptability to special environments

Deep water application: 1000m pressure resistant structure

Space Environment: Anti Atomic Oxygen Corrosion Coating

3. Intelligent development

Integrated sensor: temperature/humidity monitoring

Electronic tags: RFID identification technology

Self diagnostic function: Real time monitoring of contact resistance

4、 Deep analysis of application fields

1. Aerospace

Compliant with AS85049 standard

Weight reduction design: titanium alloy shell

Redundant contact: dual contact system

2. New energy vehicles

High Voltage Interlock (HVIL) Function

Charging interface: CCS/CHAdeMO compatible

Liquid cooling system: cooling flow rate>10L/min

3. Industry 4.0

PROFINET/EtherCAT interface

Anti electromagnetic interference: FERROSHIELD patent

Modular design: supports on-site assembly

4. Medical equipment

Sterilization tolerance: steam sterilization at 134 ℃

Anti misplacement design: color coding system

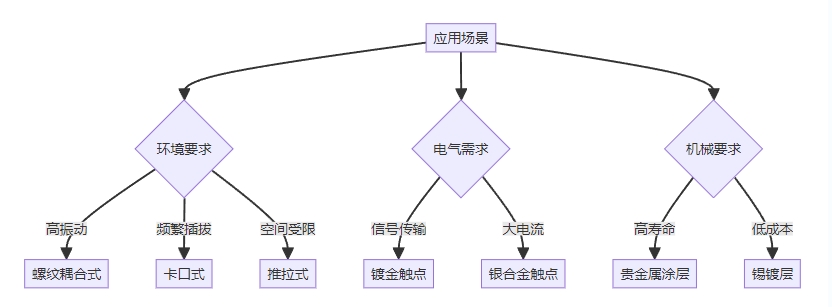

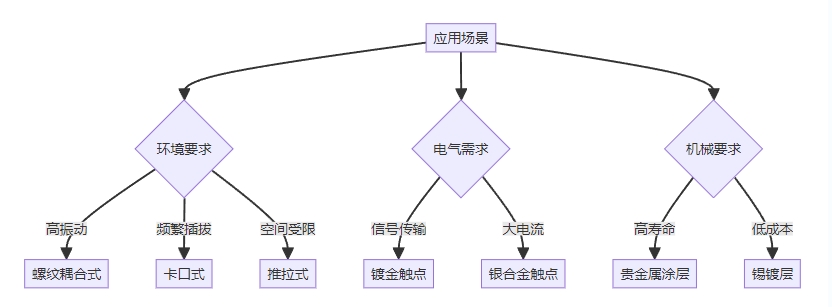

5、 Selection decision tree

Phone: 0769-83662567

Phone: 0769-83662567  Email: dg@hello1kk.com

Email: dg@hello1kk.com

Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend